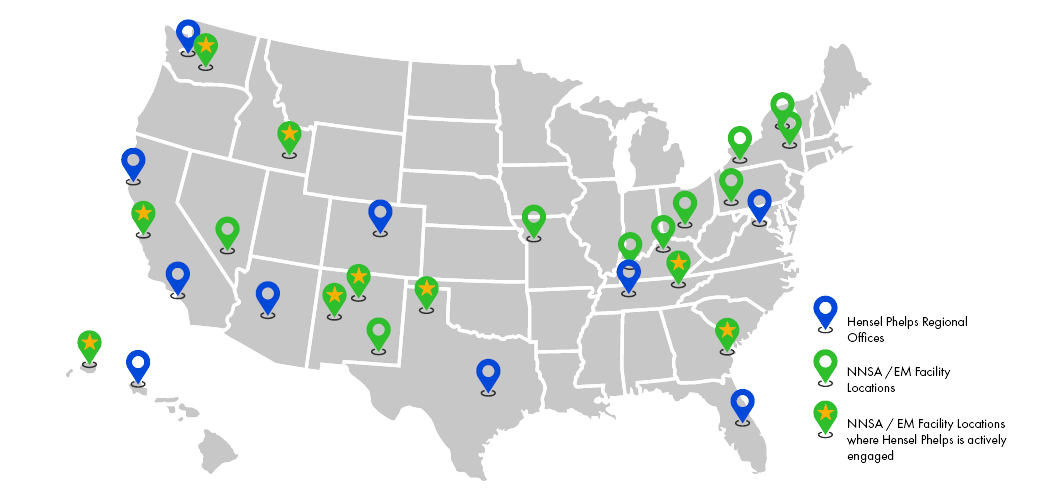

For over 20 years, Hensel Phelps has provided design, preconstruction, construction and commissioning services to the Department of Energy (DOE) and its National Nuclear Security Administration (NNSA). The NNSA, established in 2000, protects our nation by designing and delivering a safe, secure, reliable and effective U.S. nuclear stockpile. As the age of our stockpile has required an intensive modernization program, so too has the infrastructure required to rebuild this stockpile. To address this need, major construction projects are underway across the country to refurbish existing facilities and build new, state-of-the-art production complexes for the nuclear stockpile.

Hensel Phelps has delivered over 30 projects, amounting to over $1 billion across multiple NNSA sites supporting this mission. These projects include laboratories, nanotechnology facilities, educational facilities and utility and systems upgrades, all of which support national security and DOE standards. Below is a look at some of these projects and how they’re supporting the DOE and NNSA’s mission.

Los Alamos National Laboratory

Hensel Phelps has constructed over $550 million at Los Alamos National Laboratory (LANL), ranging from office buildings, laboratories and campus infrastructure.

TA-15 Dual Axis Radiographic Hydrodynamic Test (DARHT) Vessel Repair (DVR) Facility

The weapons programs at Los Alamos have one principal mission: ensure the safety, security and effectiveness of nuclear weapons in our nation’s enduring stockpile. One critical component of this mission is DARHT, the Dual-Axis Radiographic Hydrodynamic Test facility. This facility provides a dedicated space for the lab to clean out and maintain vessels supporting the overall DARHT program. The vessels contain explosive experiments that help maintain the safety and effectiveness of nuclear weapons.

TA-50 Transuranic (TRU) Liquid Waste (TLW) Facility

The Transuranic Liquid Waste facility addresses radioactive liquid generated from LANL’s plutonium facility. Constructed under the Nuclear Quality Assurance (NQA)-1 program designation, the building houses process equipment, influent storage areas, chemical storage areas and a drum preparation area.

Oak Ridge National Laboratory

Hensel Phelps was recently awarded two projects at the Oak Ridge National Laboratory.

Stable Isotope Production and Research Center (SIPRC)

The 64,000 SF SIPRC establishes the capability to produce stable isotopes on a large scale to meet the Nation’s continually increasing demands for isotopes needed in medicine, industry, science and national security, thus reducing U.S. dependence on foreign suppliers. The United States has had no existing domestic broad-scope enrichment capability since 1998, and its stockpiles of isotopes produced prior to that are being depleted.

Oak Ridge National Laboratory (ORNL) is upgrading its Spallation Neutron Source (SNS) by adding a second target station to provide transformational new neutron capabilities to advance scientific discovery and solve emerging societal challenges. STS will extend and complement the neutron capabilities of the existing SNS First Target Station and the ORNL High Flux Isotope Reactor.

Sandia National Laboratories

With over $160M delivered to Sandia National Laboratories, Hensel Phelps has been active on the Albuquerque, NM campus for over two decades.

Power Source Capability Facility

The new facility supports Sandia’s Power Sources Technology Group, which focuses on nuclear deterrence and managing the lab’s energy portfolio, including working in grid storage and battery safety. The 135,000 SF building replaces a 100-year-old facility and includes a mix of laboratory, office and other support space.

Pantex Plant

Hensel Phelps has been active on the Pantex Plant site in Amarillo, TX, since 1984, delivering over $175M in projects.

Pantex High Explosive Science & Engineering (HESE) Facility

The HESE Facility provides NNSA with the ability to perform computational and experimental research and to develop diagnostic tools for the evaluation, manufacturing support, surveillance, prototyping and testing of high-explosive materials. Construction consists of three structures – a high explosives lab facility, an equipment and staging storage facility and a technology development and deployment lab – with associated weather-proofed ramps to replace aging facilities.

Consolidated Nuclear Security (CNS), Burns & McDonnell (BMcD) and Hensel Phelps collaborated seamlessly to revise drawings, minimize project impacts and allow construction to proceed on track.

Katy Beyer, BMcD, Onsite Project Engineer.

Lawrence Livermore National Laboratory

Hensel Phelps has completed four projects at Lawrence Livermore National Laboratory (LLNL), a nuclear weapons design laboratory with responsibilities in nuclear stockpile stewardship.

B223 Polymer and Engineering Building / B224 Office Building

These two buildings are part of the first Applied Materials Engineering area plan developed by LLNL and NNSA to support stockpile stewardship.

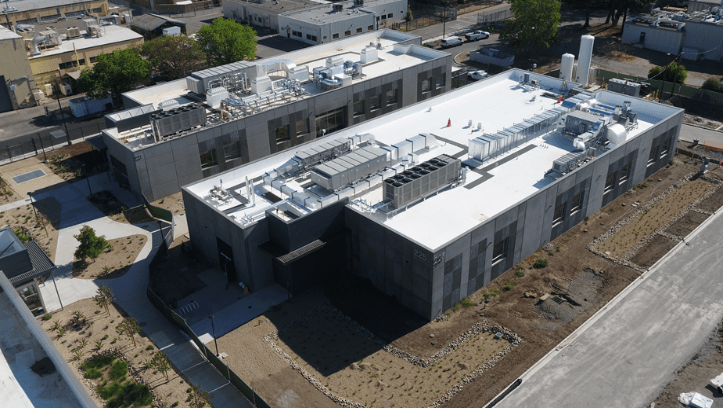

B225 Manufacturing Science Facility

The new 16,000 SF facility at LLNL houses equipment to support the polymer production mission. The facility provides an open, flexible floor plan with the capability to reduce the nuclear weapon component design and build time in support of NNSA’s W80-4 Life Extension Program (LEP) and W87-1 Modification Program requirement.