About the Project

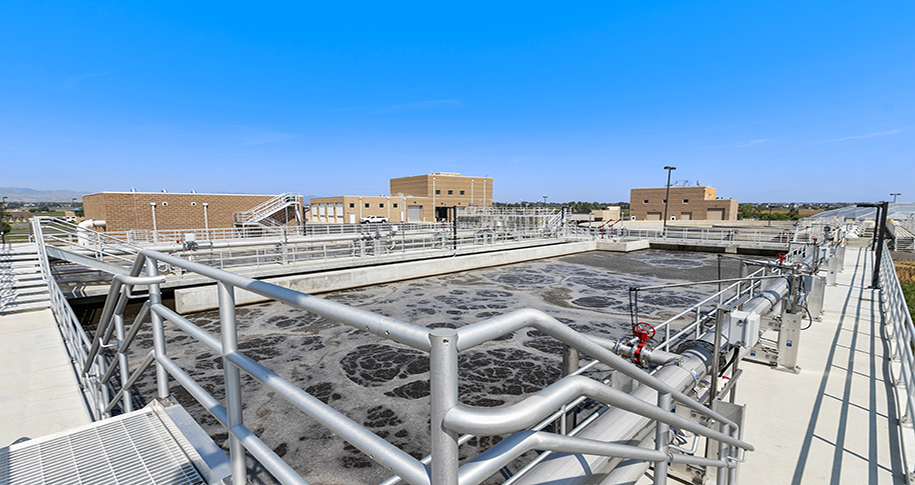

The South Fort Collins Sanitation District (SFCSD) project expanded the Water Reclamation Facility (WRF) to accommodate growth within the service area, increasing its capacity from 4.5 million gallons per day (MGD) to 6 MGD during Phase 1 (with provisions to expand to nine MGD in the future). This CMAR project included nutrient removal facilities to meet the limits of the Colorado Department of Public Health and the Environment Regulation 85.

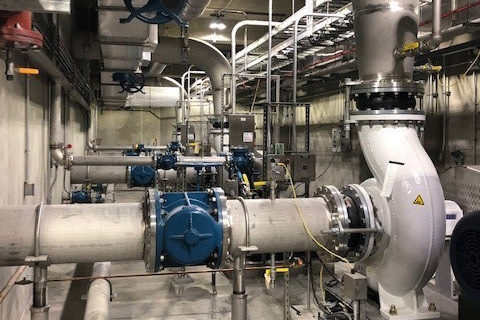

Additional improvements to the solids handling facilities enabled SFCSD to reuse their biosolids (in compliance with 40 Code of Federal Regulations Part 503 biosolids regulation) as a Class A product. The project added several new facilities including a step feed aeration basin, blower building, secondary clarifier, Autothermal Thermophilic Aerobic Digestion (ATAD) and a biofilter. Components of the project included influent pumps, blowers, numerous pumps, a UV system and rotary drum thickeners. Other improvements included yard piping, grading, paving, electrical and instrumentation and control.

“[On the SFCSD Expansion] Hensel Phelps was instrumental in providing comments, direction and support to our consultant and ourselves, while delivering an excellent product. As a team working with the CMAR delivery model, we were able to identify many areas enabling us to expand and modify the original scope while staying on time and under budget. We as owners had heavy involvement with Hensel Phelps and developed great working relationships with members of the team, concluding in a successful construction project.”

Eric Bailey, Superintendent, South Fort Collins Sanitation District, SFCSD Water Reclamation Facility Ph. 1 Expansion & Improvements

Challenge

Maintaining Operations During Construction

It was critical to maintain operations at the water reclamation facility during construction so that the 60,000+ residents and businesses in Fort Collins, Loveland, Timnath, Windsor and Larimer County were not affected by a potential disruption to service. In addition, shutdowns or any type of interruption to service always run the risk of permit violations and subsequent fines, which plant operators and owners are keen to avoid.

Solution

Ensuring Plant Operations were not Disrupted during Construction

Through early preconstruction planning, Hensel Phelps proposed reuse options that lowered cost and prevented any shutdowns of the plant, which had originally been part of the design. Hensel Phelps coordinated with the owner, plant staff and the engineer (Jacobs) during construction regarding the best way to bring the new Biological Nutrient Removal (BNR) system into operation while still operating the existing system until it could be determined that the new one proved successful.

Result

New System Implemented without Issue

This plan successfully resulted in zero lag time between taking the existing system offline and then implementing the new one. This meant that the plant was not required to shut down or enact bypass pumping at any point during construction.