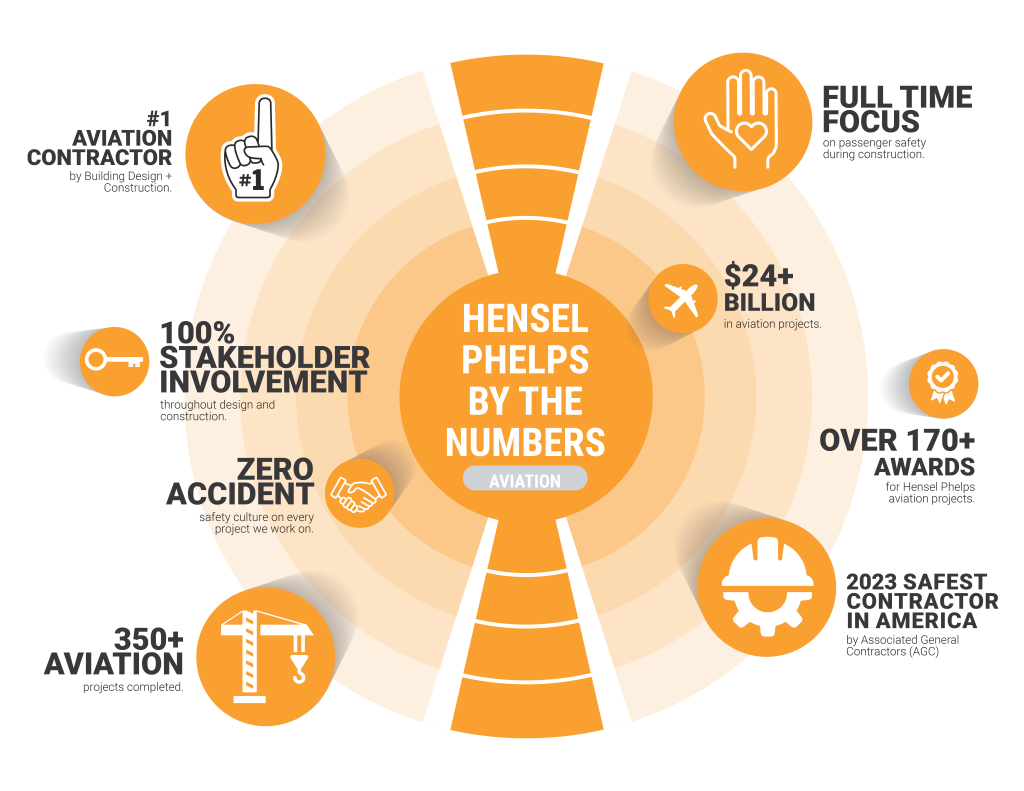

Hensel Phelps has collaborated on projects around the country that have helped shape the way people travel. They’re proud of the airports that their teams have contributed to in some of the largest cities across the nation. With extensive aviation experience, Hensel Phelps has a portfolio of over 260 airport projects nationwide, totaling over $24 billion.

Hensel Phelps’ previous experience on aviation projects brings lessons learned and responsive solutions throughout the life of every project. To be successful in an active airport, teams must be responsive and always available to adjust to the dynamic environment that working in an active airport presents. As the #1 Aviation Contractor in the United States as ranked by Building Design + Construction and Engineering News Record, Hensel Phelps understands the complexity of working within active airports–delivering projects both large and small.

About the Tampa International Airport (TPA) Main Terminal Curbside Expansion

The Hensel Phelps | HNTB design-build team designed the Main Terminal Curbside Expansion to create a new set of express arrival and departure lanes for passengers who have no need for curbside services, ticketing or checking luggage. This allows all passengers who are not checking bags with airlines to access the “Express Curb”, which bypasses the ticketing level entirely and provides faster access to the airside gates. The innovation reduces curbside congestion while providing a new and enhanced level of customer service.

The scope of the project includes the expansion from 16 to 32 lanes of traffic, incorporating both at-grade and elevated roadways, along with vertical circulation buildings (VCB) for both TPA’s Blue Side and Red Side. The VCBs are three-floor, air-conditioned atriums that provide direct access from the new express curbs to the Transfer Level of the Main Terminal via elevators, escalators and enclosed walkways. These buildings also connect to the adjacent Long Term Parking Garage on the Blue Side and the Marriott Hotel on the Red Side. The Red Side VCB also includes a Shuttle Platform that will connect with the future Airside D.

Other significant features of the Red Side VCB phase of this project include the renovation of the loading dock, replacement of the FAA parking lot, replacement of the existing curbsides’ architectural ceilings, construction of a new Police and Maintenance Department Building and demolition of the existing administration building.

How Hensel Phelps Minimizes Public Exposure at Tampa International Airport

The Main Terminal Curbside Expansion Program is a six-year renovation and expansion project that is on a very tight site. It constructs the adjoining terminal building expansions and curbside roadway expansions while maintaining 100% passenger pedestrian and vehicle access to the terminal during construction.

Minimizing public exposure to the Curbside Expansion Program is crucial for maintaining safety, preventing accidents and ensuring that the construction proceeds smoothly. The project team developed strategies to ensure that safety is at the forefront of all construction activities throughout the life of the project. Using our aviation experience, the project team achieved this by implementing the following best practices.

- Site Perimeter and Access Control

- Fencing – The fencing around the construction site perimeter is a physical barrier to deter unauthorized entry and clearly shows restricted areas for traveling passengers.

- Gates and Locks – When the construction site is not in operation, the site is secured by having all equipment put away, fencing locked and zero permitment onto the jobsite.

- Temporary Barrier Walls – These walls are to separate construction areas from travelers, employees, etc. to keep them off of the construction site.

- Authorized Personnel Only – Only authorized personnel are allowed on the jobsite and anybody who is not wearing a badge or credentials is not permitted.

- Signage and Communication

- Wayfinding – Installing wayfinding aids and signage near entrances to warn drivers and travelers and to safely direct them around construction activity.

- Signage – Hensel Phelps placed highly visible signs along the perimeter of the jobsite and entry points to indicate that the public is not authorized to enter the site.

- Public Education and Outreach

- The Hillsborough County Aviation Authority (HCAA) implemented a public outreach campaign to advise passengers about each stage of construction.

- Located on the airport’s website are articles informing locals, travelers and employees about all ongoing airport construction.

- Coordination with HCAA and the Federal Aviation Administration (FAA)

- Hensel Phelps prioritized open dialogue and collaboration through detailed coordination meetings with the owner.

- Working diligently with HCAA and the FAA to coordinate cranes on the project to ensure safe air space for all air travel at Tampa International Airport.

- Worked with HCAA to develop a phasing plan that allowed for the construction of the new pedestrian bridge to bring the passengers from the long-term parking garage over to the terminal without affecting passenger flow.

- Worksite Safety Culture

- Safety Orientation – Every worker must go through safety orientation before working on the job.

- Safety Meetings – Proactive discussions with all craft regarding the day’s activities.

- Training and Awareness – The Safety Manager ensures that every person on the jobsite takes the appropriate training before stepping foot on the jobsite.

- Regular Site Inspections

- Frequent site walks with HCAA and the Traffic Police.

- Weekly Internal Safety Audits are Performed.

- Daily Public Hazard Analysis Performed.

By implementing a combination of physical barriers, clear communication, education and technological solutions, Hensel Phelps has been able to effectively minimize public exposure and maintain a safe environment for everyone involved. Hensel Phelps uses proactive measures that are key to preventing accidents and ensuring the success of the Curbside Expansion Program at Tampa International Airport. To date, with almost 350,000 worker hours, there have been zero lost time accidents. In addition, Hensel Phelps is working around over 20 million passengers each year with tremendous success. With a continued commitment to safety, Hensel Phelps remains dedicated to their “zero-accident” safety culture.